DESCRIPTION

Basic Info.

| Center Diameter of Positioner | 140mm |

| Rotation Radius of Elbow | Max 300mm |

| Welding Gun Displacement Angle | 0-90° |

| Maximum Load | 240kg |

| Deflection Angle | 0-360 |

| Pipe Thickness | Max 1mm |

| Power Supply | 30kw/380V/50Hz |

| Welding Power Source | Otai Wsm400/Panasonic Yc-400tx |

| Pipe Length | Max 600mm |

| Clamping Outer Diameter | 20-400 |

| Transport Package | Customized Packaging |

| Specification | customized |

| Trademark | Comflex |

| Origin | China Jiangsu |

| Production Capacity | 500 Sets/Year |

Product Description

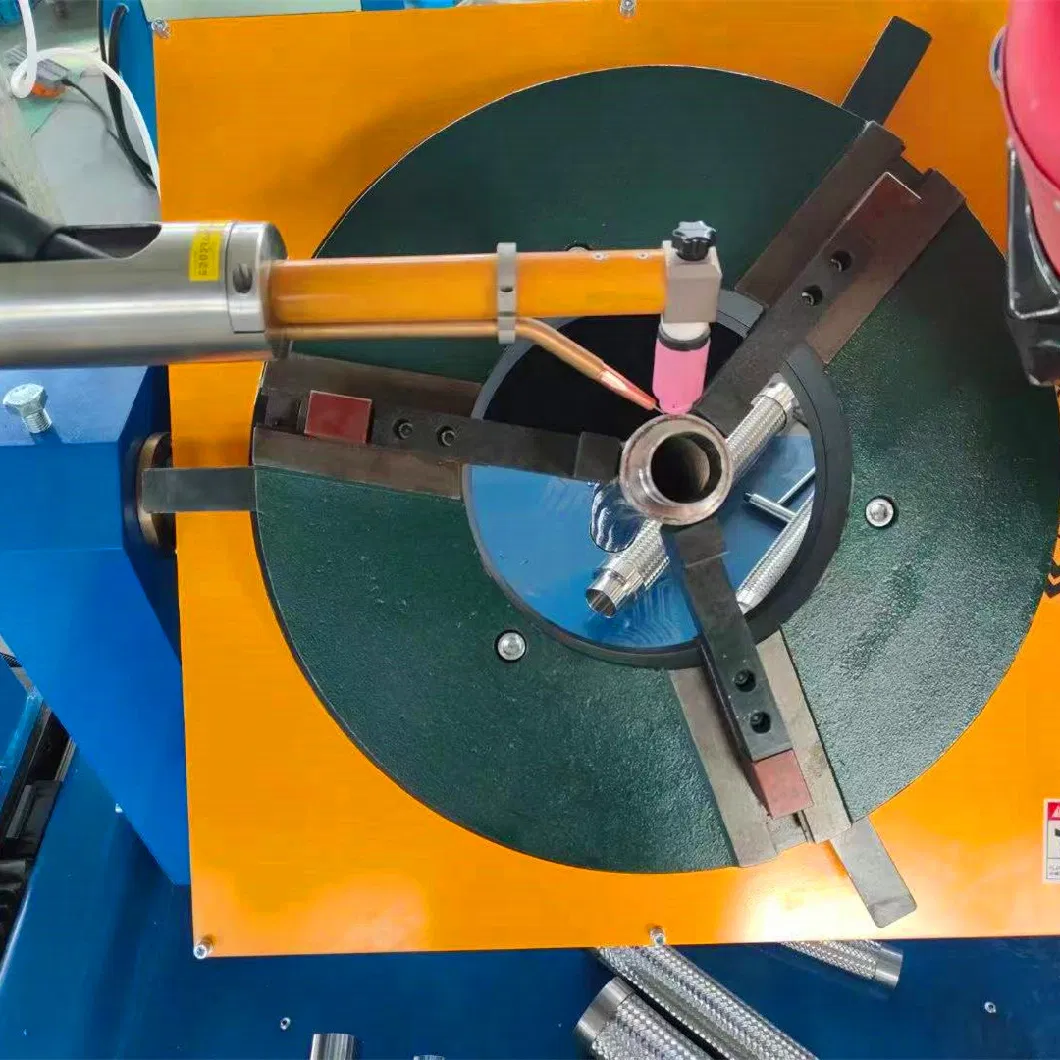

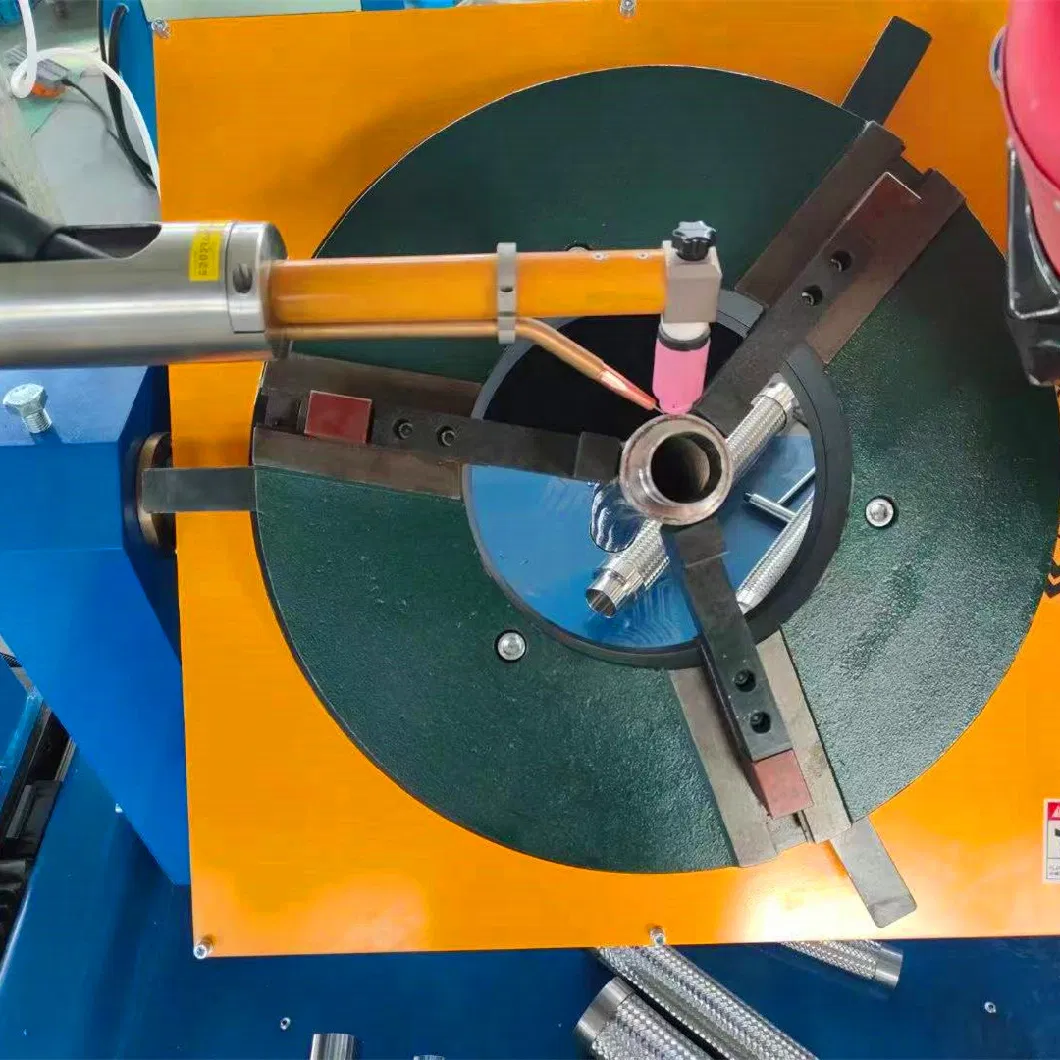

Metal Hose & Pipe End Assembly Welding machine

Product Description

1. Suitable for pipe, pipe elbow, pipe tee, pipe high neck butt joint; pipe flange, elbow flange corner joint 2. Suitable for welding of carbon steel, low alloy steel, stainless steel, copper and other materials 3. Equipped with argon arc welding equipmentSpecification1. One-piece design of the whole machine, compact structure, mature and reliable; three-jaw self-centering lathe chuck rotates and locates accurately 2. Three-dimensional welding operating arm + full-angle positioner + welding gun angle adjustment mechanism, which ensures the multi-position and multi-angle conversion of the welding gun 3. The control system adopts large-screen touch screen man-machine interface, which is convenient for programming 4. The storage capacity of welding process is 30 sets, and the corresponding welding process can be directly called according to the specifications of the weldment and according to the number. 5. Standard arc length tracking system (AVC) and welding gun yaw system (OSC) 6. Numerical control automatic wire feeder, with automatic anti-drawing function and pulsating wire feeding function, high wire feeding precision 7. Forced circulating water cooling system to ensure long-term reliable operation of the whole machine. 8. One-button operation, which automatically completes the entire welding process; you can also intervene in real-time welding parameters as needed

| Clamping outer diameter | Φ20~Φ400 |

| Tube length | Not more than 600mm |

| Pipe wall thickness | Not less than 1mm |

| Welding power | Otai WSM400/Panasonic YC-400TX |

| Power supply | Welder 30KW/380V/50Hz |

| Rotation radius of elbow | Not more than 300mm |

| Center diameter of positioner | 140mm |

| Deflection angle | 0~360° |

| Cross arm stroke (X/Y/Z) | 800mm×400mm×30mm (manual) |

| Welding gun displacement angle | 0~90° |

| Overall size | 1300mm×2000mm×1650mm |

| Total Weight | 800kg |

| Maximum load | 240kg |

| Controller | Color touch screen controller |

| Storage capacity | 30 sets of welding processes |

| Number of welding layers | Automatic layering |

| Welding Torch Oscillator | Swing range 0~20mm; swing speed 0~20mm/s; stay time on the groove side 0~5s |

| Arc length tracker | Tracking range 0~40.0mm; tracking speed 0~6mm/s; arc length tracking accuracy 0.2mm |

| Argon arc welding wire feeder | Adapt to wire diameter 1.0mm |

Details Images

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.Company ProfileWe specialize in flexible metal hose machinery with many years' experience and develop our machine technology all the time. Sofar, we have exported our machinery to many countries, such as US, Canada, Turkey, Australia, UK, Russia, Ukraine, India etc. Withthe progressive machine technology and the mature service system, we keep a pretty decent relationship with all our clients, someof them has cooperated with us for over 10 years and consecutively buy the machines from us to expand their productivity. FAQ1.Q : Can I get your price list ? A: Yes, Sure. In order to send you our available offered price. Please choose the products and let us know the product model and requirement in detail. 2

Q: Can give free sample ? A : Free : if small spare parts and the cost not too much is ok ; Not Free : the cost expensive and all the machine can not be free . 3.Q : How long can be finished the goods? Delivery date: 5-30 working days after deposit paid 4. Q: Can you customize for us?

A: Yes, we accept customize, including hose size, diameter, and pvc coating material & thickness.